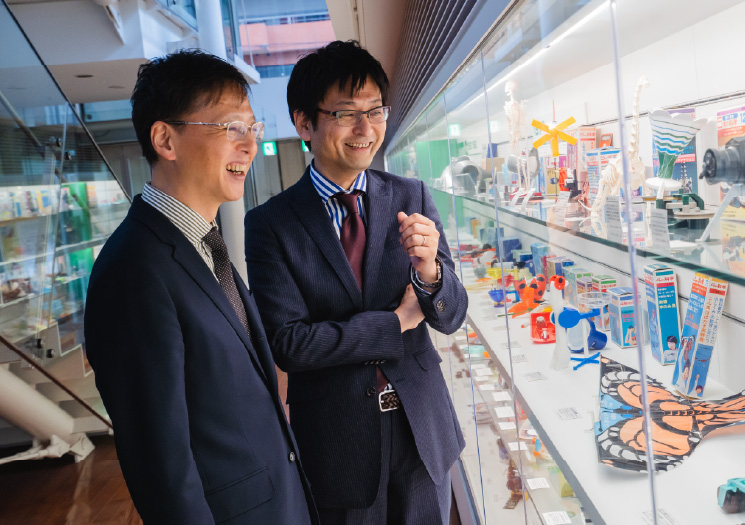

The Only Section at Japan Pulp & Paper With the Name "Stationery"

The Stationery Base Materials Section, to which Inoue and Koyama belong, is the only section named "Stationery" at Japan Pulp & Paper Co., Ltd. This is an indication that Osaka has many customers related to stationery products made of "paper," such as notebooks and envelopes. Since they carry a variety of finished products, and the customers’ requirements are also diverse, the sales department handles a particularly wide variety of materials. The lineup is broad and includes printing paper used for publications and other applications, communication papers, such as carbonless copy paper and copy paper consumed in offices, as well as oil and water resistant papers and containerboard used for packaging such as paper container boxes and lunch box containers, as well as base papers for paper products such as notebooks and envelopes. In addition to paper, the section also sells chemical products such as resins and films, as well as electric power.

Furthermore, with paper functions themselves also becoming more segmented, in order to prepare paper for each customer's products, another characteristic of the section is that it often handles "custom-made" products, in which paper is made to order. Unlike general papers for a wide range of users, which manufacturers and our company always keep in stock, "custom-made" orders are difficult to handle with substitutes, so constant attention to detail, including the ordering to manufacturers and inventory control, is essential. In addition, as mentioned above, there is a fairly wide range of items for a single section to handle, so in order to be recognized by our clients as "paper professionals," we are required to be familiar with each product and to keep ourselves updated with a wide range of information.

In the years since 2000, the Stationery Base Materials Section has been affected by social trends such as the spread of the corporate mail-order business for office supplies via the Internet, and some customers have even been forced to close their businesses. Also in recent years, schools have been closed across the board due to measures against COVID-19 infections, which together with progress made regarding teleworking of companies has spurred a decline in demand for paper products, such as notebooks and copy paper. Even if the COVID-19 pandemic comes to an end, the general industry expectation is that the paper products market will continue to shrink over the long term due to the decline in the number of children and students (declining birthrate) and the penetration of the paperless movement (digitalization).