Spreading the Charm of “Washi Fabric” to the World!

At the Japan Pulp & Paper Group, each and every employee has a sense of ownership and is part of a group-wide commitment to solving social issues, pursuing the unlimited possibilities of paper, and taking on the challenge of creating new value on a daily basis.

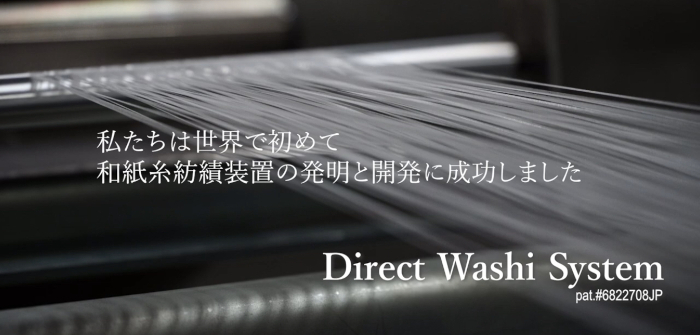

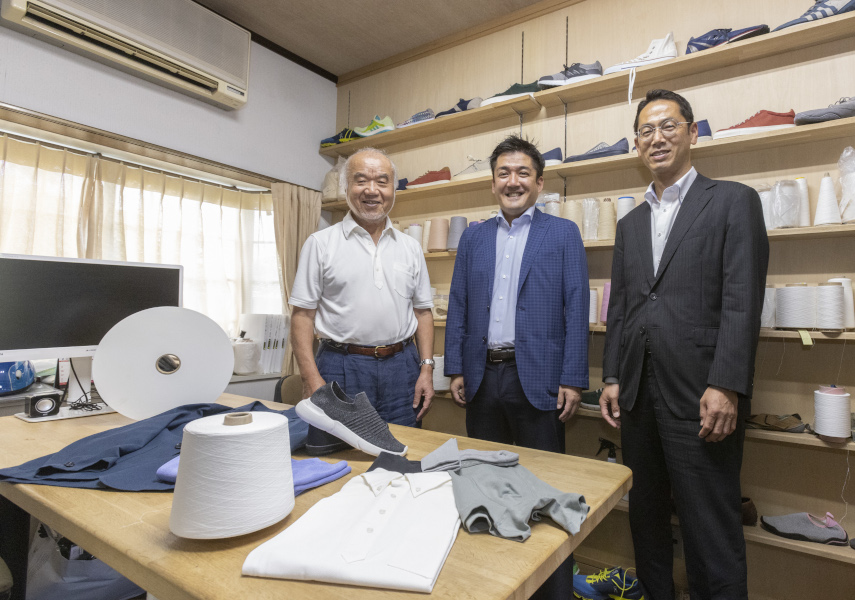

Inoue and Koyama, who belong to the Stationery Base Materials Section of the Functional Materials Department at the Kansai Branch office, discovered great potential when they encountered “paper yarn,” a functional material made from paper, during their daily sales activities. What kind of innovations can be created in the future through the collaboration between ITOI LSR Co., Ltd., which has developed a revolutionary, world first paper yarn mass-production system (Japanese Patent No. 6822708), and Japan Pulp & Paper? We are focusing on the future potential of paper yarn, and at the same time, has high expectations that the "washi fabric" products initiated by it’s president, and one of Japan’s leading washi fabric researchers, Mr. Itoi, will create new value and bring about a revolution in society.

Manager

Stationery Base Materials Section, Functional Materials Department, Kansai Branch

Stationery Base Materials Section, Functional Materials Department, Kansai Branch

CEO & President

The Only Section at Japan Pulp & Paper With the Name "Stationery"

The Stationery Base Materials Section, to which Inoue and Koyama belong, is the only section named "Stationery" at Japan Pulp & Paper Co., Ltd. This is an indication that Osaka has many customers related to stationery products made of "paper," such as notebooks and envelopes. Since they carry a variety of finished products, and the customers’ requirements are also diverse, the sales department handles a particularly wide variety of materials. The lineup is broad and includes printing paper used for publications and other applications, communication papers, such as carbonless copy paper and copy paper consumed in offices, as well as oil and water resistant papers and containerboard used for packaging such as paper container boxes and lunch box containers, as well as base papers for paper products such as notebooks and envelopes. In addition to paper, the section also sells chemical products such as resins and films, as well as electric power.

Furthermore, with paper functions themselves also becoming more segmented, in order to prepare paper for each customer's products, another characteristic of the section is that it often handles "custom-made" products, in which paper is made to order. Unlike general papers for a wide range of users, which manufacturers and our company always keep in stock, "custom-made" orders are difficult to handle with substitutes, so constant attention to detail, including the ordering to manufacturers and inventory control, is essential. In addition, as mentioned above, there is a fairly wide range of items for a single section to handle, so in order to be recognized by our clients as "paper professionals," we are required to be familiar with each product and to keep ourselves updated with a wide range of information.

In the years since 2000, the Stationery Base Materials Section has been affected by social trends such as the spread of the corporate mail-order business for office supplies via the Internet, and some customers have even been forced to close their businesses. Also in recent years, schools have been closed across the board due to measures against COVID-19 infections, which together with progress made regarding teleworking of companies has spurred a decline in demand for paper products, such as notebooks and copy paper. Even if the COVID-19 pandemic comes to an end, the general industry expectation is that the paper products market will continue to shrink over the long term due to the decline in the number of children and students (declining birthrate) and the penetration of the paperless movement (digitalization).

Grasp the Appeal and Feel of Paper Yarn

Just as unfavorable winds were blowing through the Stationery Base Materials Section, Inoue and Koyama received an inquiry from a client about "paper yarn.” Even the two experienced paper product specialists had never heard of this product before. However, after gathering information within the company, they learned about the mechanism behind paper yarn, in which thin paper is used to make the material that becomes paper yarn, and they also learned of the existence of a paper manufacturer that makes the base paper for paper yarn. “The base paper for paper yarn has a basis weight* of about 10g/m². I had never handled paper this thin, and frankly speaking, I was puzzled. How does thin paper become paper yarn? How does it then become fabric?” notes Inoue. Numerous questions arose, but we asked the paper manufacturer about each one and gradually deepened our understanding.

*Basis weight: The weight of a sheet of paper per square meter, expressed in the units g/m2. For the same brand of paper, the smaller the basis weight, the thinner the paper.

As a result, we were able to meet the client's request and have been working on product development ever since. On the other hand, as we continued to communicate with paper manufacturers who produce base paper for paper yarn, they introduced ITOI LSR to us, saying, “We would like you to work with this client.” Inoue and Koyama immediately went to the home office of Mr. Itoi, the head of ITOI LSR. The first thing that Mr. Itoi mentioned was a story about socks made of washi paper yarn. “I was surprised at how comfortable they were when I actually tried them on after receiving a sample. My own skin sensation matched the evidence that the porous nature of washi paper keeps feet dry and silky," said Koyama. This was a light in contrast to the shadow that had fallen over the paper industry. Inoue and Koyama say they felt that this would illuminate the future.

-

Washi fabric items by ITOI LSR

Washi fabric items by ITOI LSR

The Japan Pulp & Paper Group is a Driving Force Behind the Paper Culture That Includes Paper Yarn

Paper yarn, which has often been discussed from the perspective of a so-called traditional craft, is about to be transformed into an industrial product more familiar to consumers. We want to make the most of this opportunity. “In the past year, we have seen an increase in the number of articles about new products using paper yarn. We believe that this product has great potential and will continue to grow in the future. If demand increases, there will be an urgent need to strengthen the production system to meet this demand,” says Inoue. Of particular note is the "Direct Washi" paper yarn mass-production machine developed and patented by ITOI LSR. Paper yarn is generally known for its unique hardness, but the paper yarn produced by this machine is not only soft but also elastic. This machine, which utilizes the principles of handmade paper-making, also slits the machine-made washi base paper and transports it directly to the twisting machine, enabling the mass production of paper yarns. Inoue says that “If this equipment becomes widely used, more washi fabric products will enter the market. Washi paper fabric is exactly the kind of product that Japan Pulp & Paper should be involved with in the future. Our role is to purchase paper yarn base paper and distribute it to ITOI LSR, but in the future we would like to go beyond that and work together with ITOI LSR to spread the good qualities of paper yarn throughout the world.

Mr. Itoi, who was involved in the development of Direct Washi, describes the mass production enabled by this machine as "the dawn of washi yarn," and Koyama has high expectations for it as well. “Paper has functions such as “information communication,” “wrapping,” and “wiping,” but if the attribute closely related to people's lives, “wear”, also takes root, I feel that the revolutionization of the industry that Mr. Itoi hopes for is not just a dream”, says Koyama.

Inoue and Koyama, who were inspired by Mr. Itoi's passion and the appeal of washi fabric, say, "We are the right people to promote paper culture, including paper yarn.” The reason for this is the knowledge that Japan Pulp & Paper possesses. The company's knowledge of paper, as well as information on business practices, trends, and personal connections in the paper industry, reflects the efforts of its predecessors who have continued to pursue the value and potential of paper, and represents each of the many results of their sincere efforts. “We are proud that our knowledge is the best in the Japanese paper industry. Our mission is to pass on this paper culture of which we are so proud, to the next generation.

Carrying on the Stationery Base Materials Section Name

A number of washi fabric items created by ITOI LSR are already available in the market, and new applications for denim are being developed. In addition, the company expects washi fabrics to be highly versatile, transcending the boundaries of apparel. “We will continue to share with ITOI LSR about cutting-edge information on paper, and working as a leader in developing the market. Mr. Itoi's vision is to showcase the appeal of washi fabrics to the world at the Osaka World Expo in 2025, and we hope to be of assistance in realizing this vision.” (Koyama)

Inoue and Koyama agree that paper yarn is a material worthy of the Stationery Base Materials Section's name in the 21st century. Inoue and Koyama envision a future in which paper yarn will be a new pillar of the Stationery Base Materials Section, and they are taking on the challenge of creating new value through paper yarn. Inoue, in particular, is responsible for preserving the name of the Stationery Base Materials Section for future generations. "The names of various divisions have changed with the times, but I want to leave the name “Stationery Base Materials Section” of the Kansai Branch to future generations.” These were the words of Inoue's former supervisor at the time he was appointed to the Stationery Base Materials Section. Inoue believes that the name "Stationery Base Materials Section," which has remained throughout the long history of Japan Pulp & Paper, must be carried on in the future. This aspiration to keep the name of the section alive with paper yarn at its core may be what will support a sustainable society.

The information provided herein was current at the time of its announcement.

Please note that this information may be subject to change without notice.

[Published on November 28, 2022]